Designed for testing initiators, detonators, pyromechanisms and all electro-pyrotechnic devices

These firing units are designed for Conformity Of Production testing and for development tests in laboratories.

Safety features include remote interlock, removable keyed enable switch and internal error checking ensuring high user safety.

Integrated safety ohmmeter with 4-wire resistance measurement for each channel with pre and post testing features. Ability to set the upper/lower limits to determine what construes a resistance fault.

All our firing units / exploders versions are equipped with a high-performance square current pulse generator that regulates the energy delivered to the device to be tested.

Very short rise time (<10μ sec) without almost any overshoot. Removal of residual static electricity charges by means of discharge circuits in the firing lines.

“High Energy” version. For the “Low Energy” version, click here.

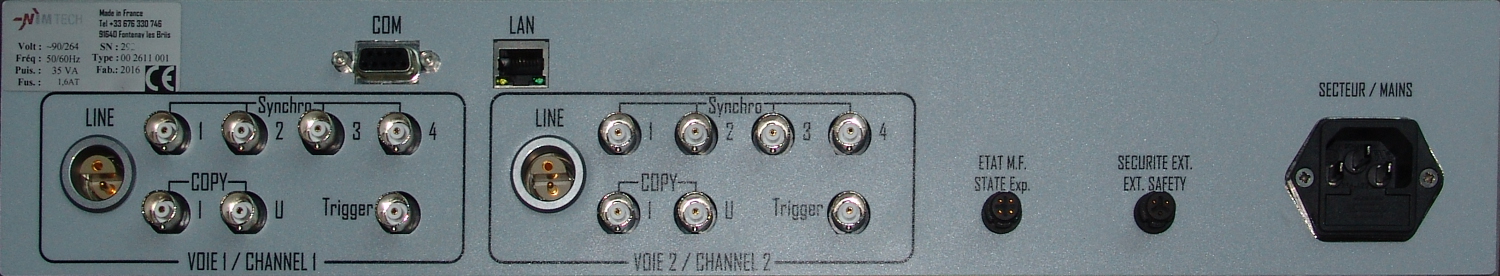

- 2 channels (possibility to cascade the devices to increase the number of channels)

- 10µs / 990s pulses 10µs time steps

- 100mA / 10A pulses 1mA current steps

- Fully controllable via RS232 or Ethernet

- 19″ Rack 2U

- Programmable Current and time

- Floating firing line (isolated)

- Independent or coupled channel

- Analog monitoring 0-10V current and voltage isolated

- Inside data acquisition V and I (Get back data over Ethernet – under develepment)

- 6 independent trigger modes on each channel

- Configurable functions (input delayed trigger, breaking load detection, …)

- Ohm meter with integrated safety

- Constant current pulse generator

- Discharge Circuits (ESD) of firing lines

- Safety devices: key, push-protected, input for external safety door contacts / barriers

- Safety circuit insulation off the line of fire safety conditions

- Internal data acquisition Current and voltage

- Testing Laboratories

- Tests Bruceton

- Characterization of initiators

- Type tests AKLV16

- Production Control

- TTT control production line (under development)